Оборудование

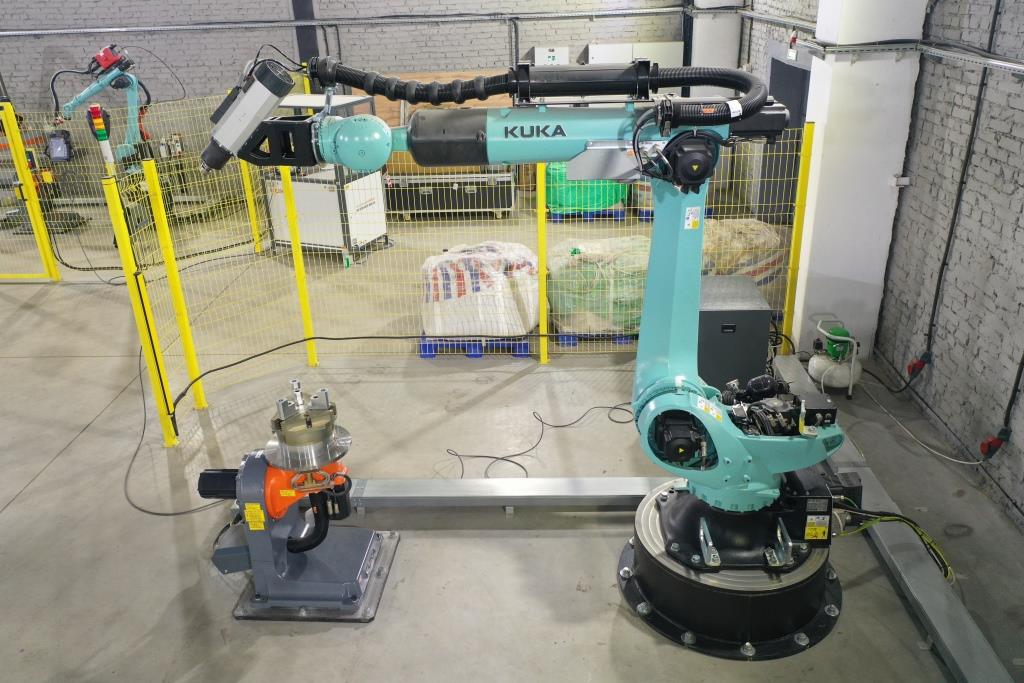

Robotic milling complex based on industrial robot KUKA KR 210 R3100-2

Precise carving of flat or three-dimensional figures from materials such as metal, wood and plastic.

The robotic complex is designed for automatic high-precision milling of products from various materials: steel, foam, plastic, composites, wood and aluminum.

The system is based on the industrial robot KUKA KR 210 R3100-2, characterized by high accuracy, reliability and a large working range, which makes it an ideal solution for three-dimensional processing of complex-shaped products.

Advantages:

- Fully automated milling process

- Ability to work with a wide range of materials

- High precision and stability of processing

- Flexibility in setting up for various tasks and geometries

- Reduced costs for manual labor and increased productivity

- The complex is easily integrated into existing production processes and can be adapted to individual customer requirements.

Purpose of the complex

This complex is designed for automatic (robotic) milling of products from foam, various types of plastic, composite materials, wood and aluminum. This robotic technology is used in the production of automotive components (for example, when trimming the flash of molded elements of the exterior and interior of cars), the manufacture of model equipment in foundries, for creating art objects and conceptual models of various new products (cars, boats, etc.), cutting holes in large-diameter plastic pipes, etc.

Complex composition

- Industrial robot KUKA KR 210 R3100-2. Load capacity 210 kg, reach 3100 mm

- Two-axis positioner. Load capacity 500 kg, equipped with a three-jaw chuck for clamping workpieces

- Spindle

- Tool change system

- Protective guard kit