Оборудование

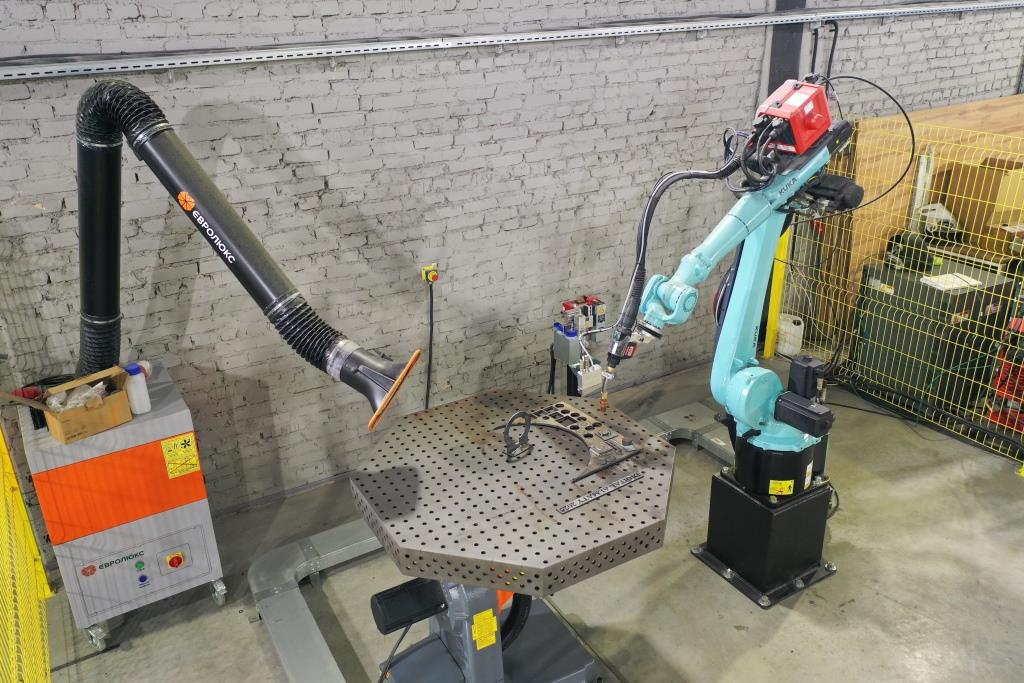

Welding robotic complex based on industrial robot KUKA KR 16 R2010-2

Flexible and multifunctional robot.

This complex is designed for automatic electric arc welding using a consumable electrode in a protective gas environment. It ensures high-quality joining of parts made of various types of metals and covers a wide range of products. The key feature of the complex is the use of advanced Fronius CMT (Cold Metal Transfer) welding equipment — a patented cold metal transfer technology. This allows for precision welding of not only carbon steels, but also alloy steels and aluminum with minimal thermal deformations and high weld stability.

Advantages of the complex:

- Process automation — high productivity and stable quality due to full robotization;

- Flexibility in use — suitable for welding products of varying complexity and geometry;

- Expanded material capabilities — welding ferrous, stainless and non-ferrous metals;

- Low heat input — thanks to CMT technology, the risk of deformations and burns is reduced;

- Increased reliability of welded joints — even when working with thin-walled materials.

Complex composition

- Industrial robot KUKA KR 16 R2010-2, Load capacity 16 kg, reach 2010 mm

- Two-axis positioner, Load capacity 500 kg

- Fronius welding equipment with CMT technology, Welding current - up to 400A

- A set of equipment for fastening tooling and parts to the positioner. Octagonal tabletop with holes for fastening tooling, installed on the positioner

- Filter and ventilation unit. Removal of harmful substances emitted during the burning of the welding arc

- Machine vision. Machine vision is implemented on the basis of a triangulation sensor designed to search for welded joints and track the seam

- A set of protective fencing